CFD + Process Modeling

REI’s extensive experience in boiler CFD modeling, is now combined with steam-side process simulation to guide :

• Heat transfer surface modification

• Heat balance

• Fuel quality impacts

• Coal to gas conversion

Process Model

Overall heat and mass balances for the boiler

Couples together fireside and steam side heat transfer

Predictions of heat transfer in convective section

CFD Model

3D multiphase, turbulent, reacting flow simulations in radiant section

Thermo-chemical predictions are used within the radiant section of process model

Emissions predictions

Slagging predictions

Impacts of heat transfer modification and surface cleaning in radiant seciton

Oxy-Coal Combustion Project Summaries

REI’s process model SGE and CFD model Glacier were used to investigate two oxy-coal firing retrofits of existing coal-fired units. In each case, the process model was used to evaluate the impact of recycle rate on heat transfer in both the radiant and convective sections of the furnace. The SGE model includes a module for the lower furnace which can be configured to represent the actual geometry of the unit where radiation calculations are performed using the emissive properties of mixtures of gases and a predefined heat release profile from the fuel. The process model included coal mills, a lower furnace model which resolved multiple rows of burners on each the front and rear walls along with OFA, secondary superheat platen and pendants, reheater with both vertical and horizontal tube sections, primary superheater, economizer, attemperation and flue gas recycle.

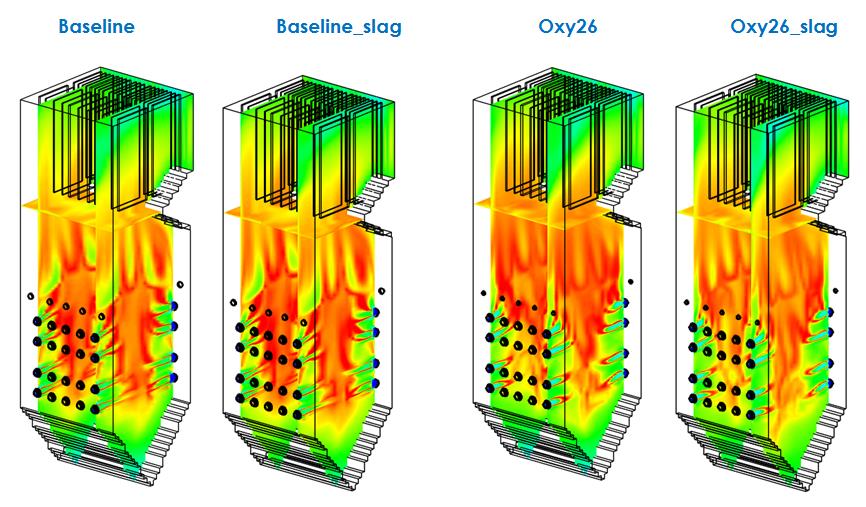

Following the process modeling, CFD models of the radiant furnace were performed at 26% O2 (wet) in the O2 / FGR mixture. Various CFD cases were run with enhanced radiation, char oxidation, and soot sub-models to evaluate:

The behavior of oxy-coal combustion in a full-scale utility boiler compared with the existing air-fired behavior including

Heat transfer profiles,

Corrosion potential of the waterwalls and superheat surfaces,

Deposition profiles and rate in the radiant furnace,

Combustion Efficiency (CO and UBC),

The impact of coal sulfur concentration and flue gas cleaning before recycle.