Mercury

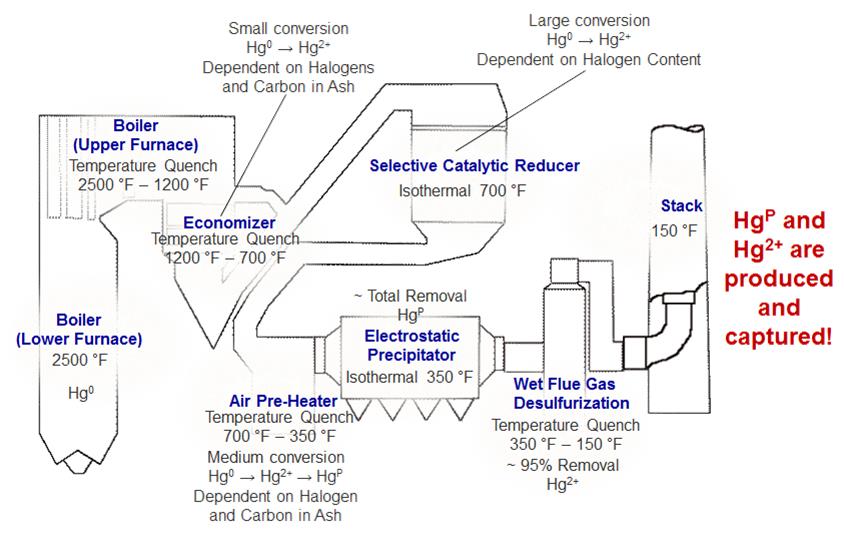

REI has extensive expertise in mercury behavior, from mercury control technology assessments to compliance strategies and prediction of mercury emissions. With in-house mercury measurement equipment, REI can provide mercury testing support from lab-scale to pilot- and full-scale demonstrations. REI’s mercury process model, MerSim, can be used to evaluate potential operating changes or technology additions to predict changes in mercury emissions. Custom models for new technologies are also possible. REI can also provide Computational Fluid Dynamics Modeling to asses mixing and distribution for sorbent injection.

Mercury Control Assessment can include:

- Detailed plant analysis

- Planning, oversight, and review of measurement campaigns to characterize current mercury emissions and removal of mercury by existing air pollution control equipment

- Screening and recommendation of appropriate mercury control technologies

- Experimental evaluation of control strategies: pilot and full-scale demonstration

- Predictive evaluation of control strategies using detailed process simulations

- Hg control demonstration planning, management, and analysis

- Thorough understanding of mercury measurement techniques and mercury mass balance

- Comprehensive CFD modeling to address mixing and distribution issues

- Analysis of specific coal sources to determine if the plant can maintain compliance if fuels are changed

- Assessment of current and future compliance status to determine if existing equipment can be tuned to improve mercury reduction

- Evaluation of pollution control device impacts on plant mercury emissions to determine how planned Air Pollution Control Devices (APCD) changes will impact current emissions

REI Advantages:

- Leader in modeling mercury chemistry

- Independent, third-party assessment

- Experts in control technologies and compliance strategies