MerSim

With EPRI support, REI has developed an integrated process model, MerSimTM, for predicting mercury behavior based on fundamental mechanisms that allow for meaningful extrapolation to new situations, not merely interpolation. MerSim is a useful tool which may be used to investigate possible compliance strategies for mercury emissions control. It is a user-friendly, module-based model which uses inputs typically known by the utility. MerSim has been developed and validated using 144 data sets from 28 full-scale power plants. It includes homogeneous and heterogeneous oxidation kinetics, adsorption on fly ash, oxidation across SCRs, and removal and re-emission across wet FGD scrubbers. It can represent impacts of halogen addition and activated carbon injection. Detailed SO3 calculations are also performed in MerSim to account for interference with mercury removal.

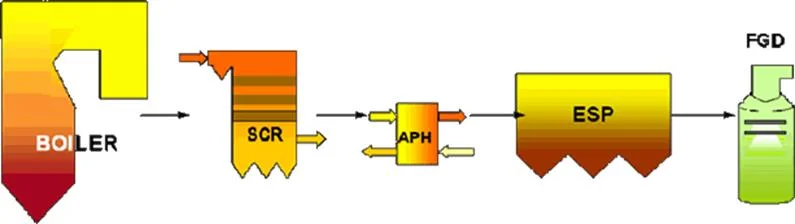

MerSim includes the following modules:

- Boiler

- Air Preheater (APH)

- Selective Catalytic Reduction (SCR)

- Hot-side Electrostatic Precipitator (HESP)

- Cold-side Electrostatic Precipitator (CESP)

- Fabric Filter (FF)

- Spray Dryer Absorber with Fabric Filter (SDA-FF)

- Ductwork

- Wet Flue Gas Desulfurization (wFGD)

MerSim can be used to evaluate compliance strategies:

- Analysis of specific coal sources to determine if the plant can maintain compliance if fuels are changed

- Assessment of current and future compliance status to determine if existing equipment can be tuned to improve mercury reduction

- Evaluation of pollution control device impacts on plant mercury emissions to determine how planned Air Pollution Control Devices (APCD) changes will impact current emissions

- Investigation of mercury-specific control technologies