Rich Reagent Injection

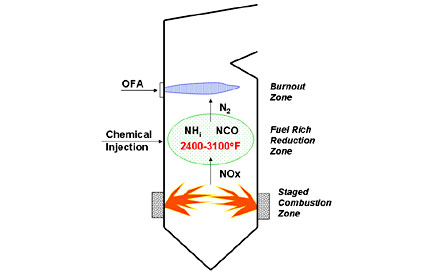

Rich Reagent Injection (RRI) is a new NOx control technology that provides coal-fired generating units with a cost-effective means of complying with NOx regulations. The RRI process reduces NOx formation by injecting amine-based compounds into the fuel-rich regions of furnaces. The RRI process was originally developed for coal-fired cyclone boilers, and performs well in the fuel-rich lower furnace created by operating cyclone boilers with overfire air. Combined overfire air and RRI technologies have been shown to reduce cyclone NOx levels by more than 80%. The RRI process is also applicable to other pulverized coal-fired units and industrial boilers.

RRI is a complementary technology that can be coupled with other NOx reduction technologies such as low-NOx burners, overfire air, and Selective Non-Catalytic Reduction (SNCR). The RRI process is particularly compatible with SNCR as it uses similar chemicals and hardware, providing SNCR users a familiar operational environment and economies of scale in capital costs. For applications where ammonia slip is a concern, RRI provides a beneficial alternative since it produces no ammonia slip.

RRI development started with chemical kinetics modeling and advanced computational fluid dynamics (CFD) modeling at REI. This was followed by extensive laboratory testing at the University of Utah and finally two full-scale demonstrations on EPRI-member utility units, Conectiv’s 160 MW B. L. England Unit 1 and AmerenUE’s 480 MW Sioux Unit 1.